By Howard Herndon

There has been much confusion in the industry concerning arc energy reduction systems and the corresponding NEC requirements. This article is intended to clarify the requirements, types of systems and the setup required in the field by the installer or owner. The instant energy levels of equipment are heavily based on two major factors, Time and the amount of energy (Short Circuit Current). If it were possible, the time settings on all overcurrent devices would be lowered and the equipment trip faster but, in most circumstances, this is not possible for the coordination of equipment and the conductivity of the electrical system.

The intent of the Arc Energy Reduction System is to speed up the trip time of the overcurrent device. This lowers the instant energy levels and reduces the potential injury to personnel and equipment when workers are working on or interfacing with the equipment. The energy reduction system provides 2-set point for the equipment main or feeder 1200A or larger, 1-set point for the maintenance of equipment (the lower of maintenance setting) and 1-for normal operation.

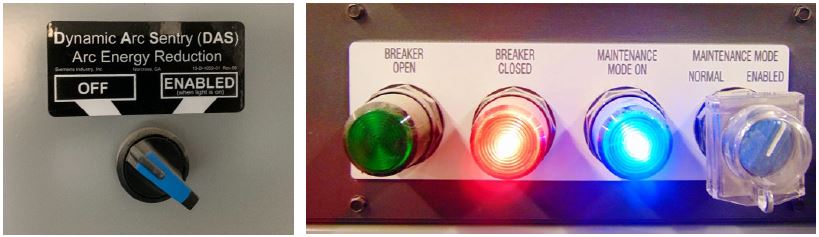

This system is typically controlled by a switch located in the area of the 1200A or larger device.

The requirements are as follows per the NEC 240.87 (Breakers)

Where the highest continuous current trip setting for which the actual overcurrent device installed in a circuit breaker is rated or can be adjusted is 1200 A or higher

Documentation shall be available to those authorized to design, install, operate, or inspect the installation as to the location of the circuit breaker(s).

Method to Reduce Clearing Time. One of the following means shall be provided:

• Zone-selective interlocking

• Differential relaying

• Energy-reducing maintenance switching with local status indicator

• Energy-reducing active arc flash mitigation system

• An instantaneous trip setting that is less than the available arcing current

• An instantaneous override that is less than the available arcing current

• An approved equivalent means

The most popular used system by most manufacturers for low voltage systems is the energy reduction switch with status indicator.

The requirements are as follows per the NEC 240.67 (Fuses)

Where the fuse rating is 1200 A or higher

Documentation shall be available to those authorized to design, install, operate, or inspect the installation as to the location of the circuit breaker(s).

Clearing time of fuse must be .07-seconds based on the available arcing current at that point in the system, otherwise a method to reducing clearing time shall be provided:

• Differential relaying

• Energy-reducing maintenance switching with local status indicator

• Energy-reducing active arc flash mitigation system

• An approved equivalent means

To date and to my knowledge the only way to use fuses is to calculate the clearing time of the fuse based on the system available short circuit and the fuse clearing time. There are a couple of systems under development at this time.

The arcing current as stated in both the breaker and fuse requirements is NOT the short circuit current. The arcing current is current flowing through the air between phase conductors or phase conductors and neutral or ground. This is calculated based on the short circuit current available at the device and the clearing time of the device. This is typically calculated through software as part of the electrical systems Arc-Flash Study.

The first step for compliance of the NEC 240.87, 240.67 is understanding the system and the equipment details available at the time the equipment is ordered. Note the NEC requirement is not bound by a voltage rating so, this applies to both 208Y/120 and 480Y/277 Volt systems. Also, worth noting, the requirement states the overcurrent devices shall be provided with an arc energy reduction system where the device is rated or can be adjusted to 1200A or larger. For example: if you have an 800A or 1000Amp device with a 1200A frame, the maximum of that overcurrent device is 1200A and the NEC arc flash mitigation requirement would be in effect.

New electrical systems for commercial and small industrial applications are most often designed without firm knowledge of the detailed utility supply to the system and often provide limited details on the loads in the system. These facilities are also often built or permitted as “Shell” and “Tenant Improvements”. In most cases without the details at the time of design, including the manufacturer and overcurrent devices being used, arcing current cannot be calculated. In these situations, the practical approach should be to have an Energy Reducing System installed on each of the devices capable of 1200A and larger by the manufacturer for compliance with the NEC.

The second step, after all the details of the electrical system have been provided, the setting points must be calculated by the agency performing the Short Circuit, Coordination and Arc-Flash Study. There should be two setting points, one for normal operation and one for maintenance operation. This will require a label for each operational state.

The third step is to set the overcurrent devices with the set points as calculated in the Short Circuit, Coordination and Arc-Flash Study. Each overcurrent device should be set as per the study. If the system will be compromised when in the maintenance mode, such circumstance should be clearly noted in the report and it would be very practical to have them noted on the equipment as well. These settings are required for the system to properly operate and in most cases, cannot be set up by the manufacturer at the time of equipment shipment. This is clearly a safety device that is there to protect the electrical worker, a comprehensive study of the electrical system and proper field adjustments of the overcurrent devices are a must.

The fourth step is documentation. The documentation of the system study and calculations should be made available to the AHJ and those who design, inspect, and operate that electrical system. This is now a living document. The requirements of the NFPA70E states this report shall be reviewed, when changes in the system occur and not to exceed five years.

The 2017 edition of the NEC does not require these overcurrent devices and arc mitigation systems to be tested, this was covered in depth in the 2020 NEC edition.

One added requirement pertaining to the Arc-Flash Hazard, is the marking requirements of 110.16 (B) for 1200 Amp and larger services. The NEC requires marking of the service with the system voltage, the calculated available fault current, main overcurrent device clearing time and the date these calculations were made. There is an exception to this label requirement if, arc-flash warning labels have been provided for the system that are in compliance with NFPA70E. In the case of calculating the above requirements for the arc energy reduction systems and arc-flash labels, the labeling detail of 110.16 (B) would not be required.

If you have questions you can contact Howard Herndon at hherndon@proec.biz

Howard Herndon is President of EPC (Electrical Professional Consulting) an electrical consulting firm based in Las Vegas, Nevada. Howard has over 40 years of experience in various fields in the electrical industry. Howard also serves as the executive director of ESP (Electrical Safety Professionals) which provides the Nevada Electrical Qualifications Cards and educational services for the electrical and safety industry.